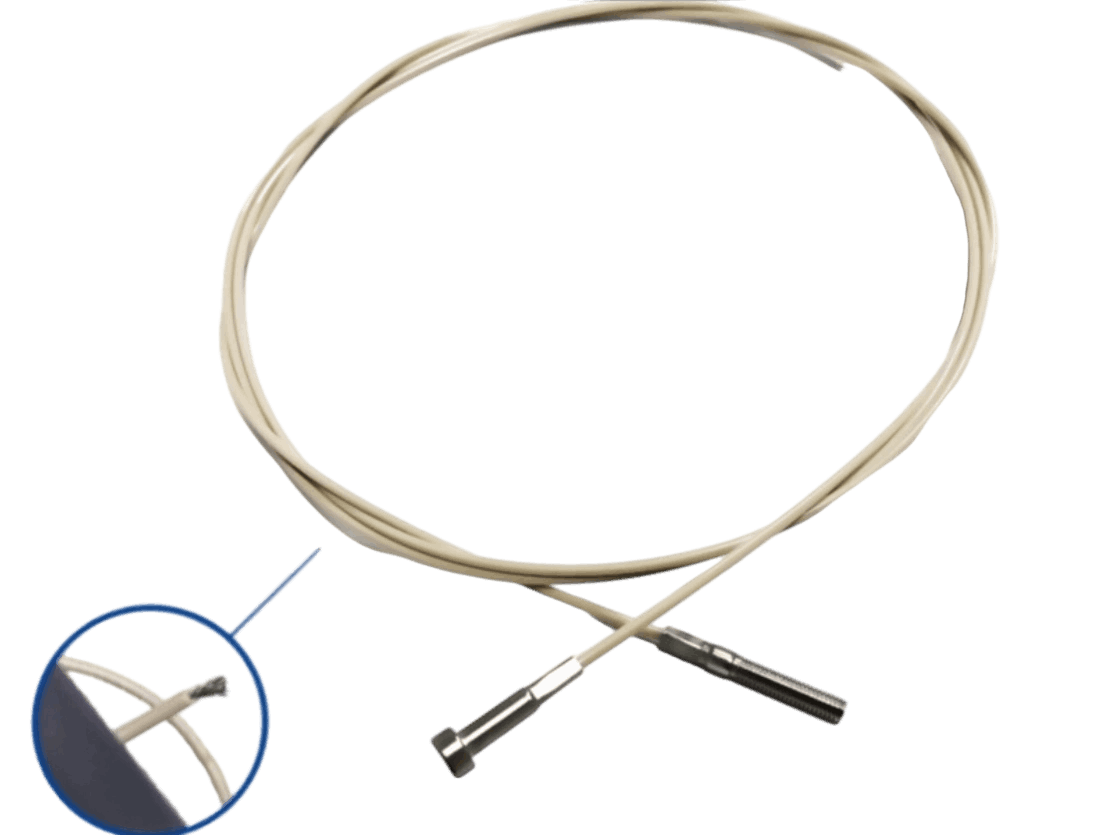

StructurePEEK LCD Cassette Support Wire

Specially designed for glass substrate cassettes, it can significantly reduce particle generation; ultra-high purity and low outgassing properties prevent contamination.

Prods

Specifications

- Temperature:-70~260℃

- Insulation Thickness:0.5~0.75mm

- Voltage Size:5KV(DC)

- Flame Retardant:VW-0

- Core Count:Single Core

- Conductor Material:Stainless Steel Wire Rope

- Insulating Material:PEEK

Applications

- Semiconductors

- Wafer Cassette Systems

- Cassette Support Cables

- Signal Transmission Components

- High-Purity Automation Equipment

- Cleanroom Mechanical Support Components

- Clean Motion Support Components

- Clean Tension Support Components

Product Detail

PEEK LCD Cassette Support Wire - Technical Documentation

Overview

PEEK support filament is integrated into the cartridge and plays a role in carrying, transporting, and protecting glass substrates during various TFT-LCD manufacturing processes.

Technical Specifications

| Parameter | Value | Unit | Standard |

|---|---|---|---|

| Density | 1.32 | g/cm³ | ISO 1183 |

| Notched impact strength | ≥5 kJ | /m² | ISO 180/1A |

| Tensile strength | ≥101 | MPa | ISO 527 |

| Thermal Expansion Coefficient | 40~50 x 10⁻⁶ /K (23-100°C) | - | ISO 11359-2 |

| Melting Point (Tm) | ≥ 343 | °C | ISO 11357-3 (DSC) |

| Flexural modulus | 3.8 | GPa | ISO 178 |

| Surface resistivity | 10⁶ ~ 10⁹ Ω/sq | - | ANSI/ESD STM11.11/11.12 |

| Outgassing (TML/CVCM) | Meets or exceeds SEMI E49, NASA ASTM E595 | - | ASTM E595 |

Material Composition

| Component | Material | Percentage | Application |

|---|---|---|---|

| Main Material | Stainless Steel Wire Rope | 85% | Main Conductor Core |

| Sheath Layer | PEEK | 8% | Provides insulation, high temperature resistance, chemical resistance, and low outgassing requirements for clean rooms |

| Functional Additives (Optional) | Carbon Fiber / Glass Fiber | 2~5% | Enhances rigidity |

Performance Features

- High wear resistance and self-lubricating properties.

- High purity and low outgassing.

- High-temperature resistance.

- Chemical resistance.

- Dimensional stability.

- Corrosion resistance and aging resistance.

- Controlled thermal expansion and anti-static properties.

Chemical Resistance

| Chemical | Resistance Level | Remarks |

|---|---|---|

| Acids | Good | Tested with dilute H2SO4, HCl3 |

| Alkalis | Good | Tested with dilute KOH, NH4OH |

| Organic Solvents | Good | Resistant to swelling or degradation |

| Oils | Excellent | Resistant to swelling or degradation |

| Fuels | Excellent | Resistant to swelling or degradation |

Temperature Resistance

| Temperature (°C) | Mechanical Property Changes | Applicability |

|---|---|---|

| ≤260 | Maintains ≈95% strength | Stable for long-term high-temperature operation |

| 300 | Decreases to ≈80% strength | Limited to short-term use |

| ≥350 | Significant performance decline | Not recommended for use in this environment |

Application Areas

- Semiconductor wafer cassette systems: Used as support cables for positioning wafers or signal transmission components.

- High-cleanliness automated equipment: Mechanical movement, stretching, and support applications in cleanroom environments.

Usage Guidelines

- Operation: Always wear cleanroom gloves. Avoid contact with skin oils or contaminants. Hold by the ends whenever possible.

- Installation: When installing PEEK support cables, avoid excessive force or twisting to prevent damage. Install the support cables accurately according to the cassette design requirements to ensure secure installation.

Maintenance

Under normal operating conditions, inspection items include:

- Inspection: Regularly inspect the wear condition, surface integrity, and connection stability of the support line. If severe wear, breakage, or loosening is detected, replace the support line promptly to ensure normal equipment operation.

- Temperature: Do not exceed the specified continuous operating temperature for the PEEK grade. Avoid rapid thermal cycling whenever possible.

- Cleaning: Before and after use, it is recommended to clean the support lines with a clean, lint-free cloth or specialized cleaner to remove any dust or debris on the surface. However, avoid using cleaners that are corrosive to PEEK material.

Certification

| Certification | Standard | Region |

|---|---|---|

| RoHS | RoHS 2011/65/EU | Europe |

| ANSI-ESD | S20.20 | United States |

| FDA | 21 CFR 177.2415 | United States |

| ISO | ISO 9001:2015 | Global |