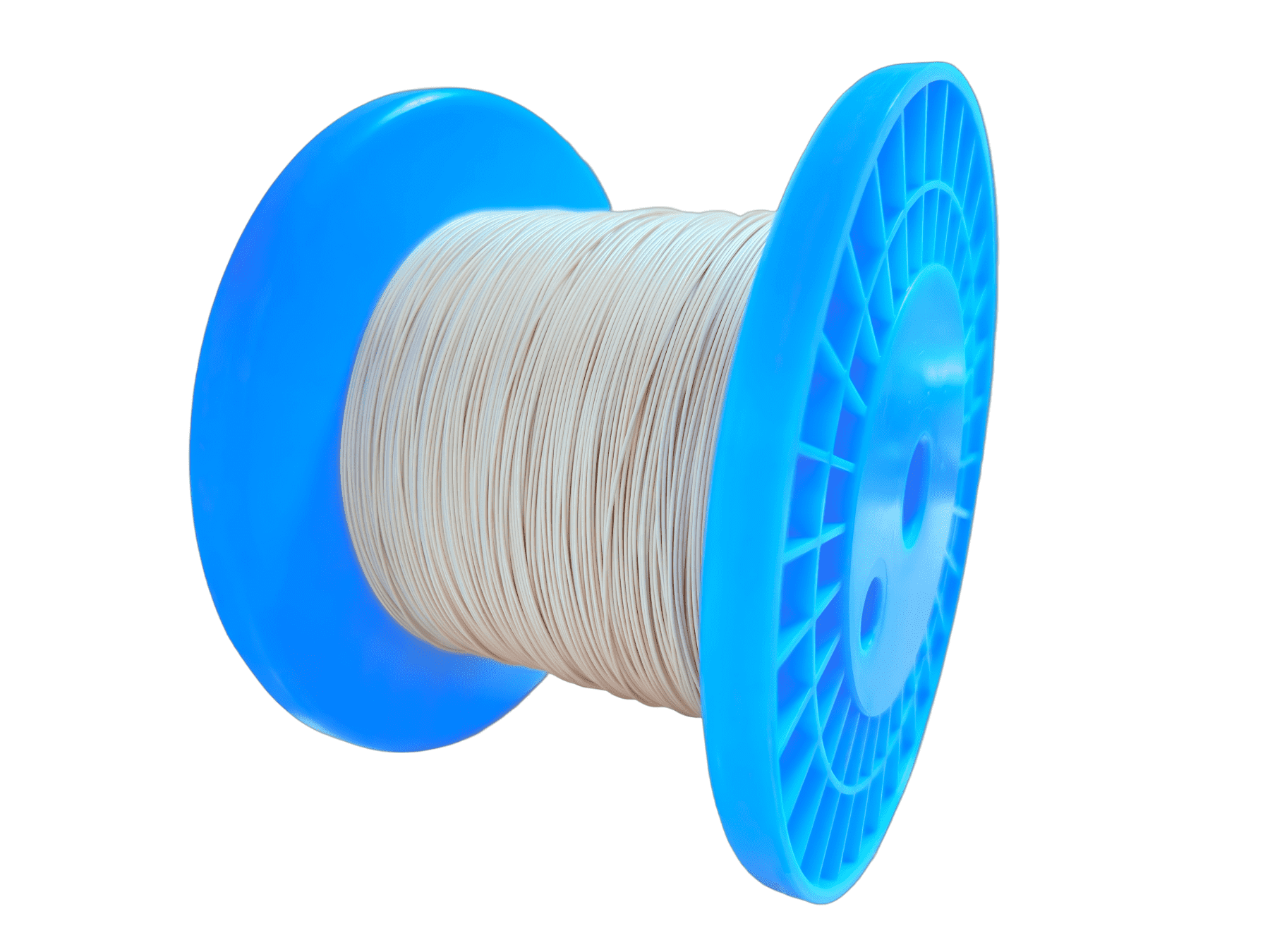

CablesPEEK 3D Printing Filament

Designed specifically for industrial-grade additive manufacturing. Features excellent thermal stability, mechanical strength, and biocompatibility.

Specifications

- Temperature:-70~260℃

- Flame Retardant:VW-0

Applications

- Aerospace

- Structural components

- High-temperature resistant kits

- Medical devices

- Implantable contact parts

- Chemical process equipment

- Corrosion-resistant parts

- Mold replacement parts

- Fixture replacement parts

- Wear-resistant replacement parts

- Terminal functional replacement parts

- High-temperature electronic insulation

- Structural support components

Product Detail

PEEK 3D Printing Filament - Technical Documentation

Overview

PEEK 3D printing filament is made from high-purity polyetheretherketone material and is specifically designed for industrial-grade additive manufacturing. It offers excellent thermal stability, mechanical strength, and biocompatibility.

Technical Specifications

| Parameter | Value | Unit | Standard |

|---|---|---|---|

| Melting Point | 343 | °C | ASTM D3418 |

| Glass Transition Temperature | 143 | °C | ASTM D3418 |

| Continuous Use Temperature | 260 | °C | ISO 2578 |

| Printing Temperature | 360~420 | °C | - |

| Bed Temperature | 160~250 | °C | - |

| Filament Diameter | 1.75 / 2.85 | mm | - |

| Filament Diameter Tolerance | ±0.05 | mm | ISO 178 |

| Density | 1.26 | g/cm³ | ISO 1183 |

| Tensile strength | 93 | MPa | ISO 527-2 |

| Flexural modulus | 3.8 | GPa | ISO 527-2 |

| Melt flow rate (380°C/5kg) | 5~25 | g/10min | ASTM D1238 |

| Flame retardant rating | V0 | - | IEC 60695-11-10 |

Material Composition

| Component | Material | Percentage | Application |

|---|---|---|---|

| Main Material | PEEK | 95% | Main Conductor |

| Anti-degradation Additives | Antioxidants / UV Stabilizers | 0.3% | Enhance thermal stability |

| Functional Additives (Optional) | Carbon Fiber / Glass Fiber / Conductive Fillers | 0~30% (depending on formulation) | Improve rigidity, conductivity, or thermal conductivity |

Performance Features

- Excellent chemical resistance.

- High mechanical strength.

- Excellent dimensional and printing stability.

- Fatigue resistance and high-temperature tolerance.

- Good sliding and wear performance.

- Excellent flame retardancy (UL-94 V-0)/CMP/VW-1, with minimal smoke emission.

Temperature Tolerance

| Temperature (°C) | Mechanical property change | Applicability |

|---|---|---|

| 25 | Baseline | Optimal performance |

| 150 | ≈No change | Long-term use stability |

| 200 | Maintains ≈95% strength | Suitable for high-temperature long-term operation |

| 260 | Maintains ≈90~95% strength | Upper limit for continuous operation |

| 300 | Decreases to ≈80% strength | Limited to short-term use |

| ≥350 | Significant performance decline | Not recommended for use in such environments |

Chemical Resistance

| Chemical | Resistance Level | Notes |

|---|---|---|

| Acids | Good | Excellent resistance to most acids (some strong oxidizing acids require verification) |

| Alkalis | Good | Tested with NaOH and KOH |

| Organic Solvents | Good | Stable against ketones, esters, and hydrocarbons (some solvents require verification) |

| Oils | Excellent | Resistant to swelling or degradation |

| Fuels | Excellent | Resistant to swelling or degradation |

Application Areas

- Aerospace structural components and high-temperature resistant kits

- Medical devices and implantable/contact components

- Chemical process equipment and corrosion-resistant parts

- Molds, fixtures, wear-resistant components, and end-use functional parts replacing metal components

- High-temperature insulation and structural support components for electronics

Usage Guidelines

- Nozzle: It is recommended to use high-temperature alloy or ceramic nozzles with a temperature resistance of ≥420°C.

- Heat bed: 160~250°C; use a high-temperature-resistant build plate (PEEK, Garnet glass + high-temperature adhesive or special adhesive).

- Print chamber: Recommended to be enclosed and heated, with a chamber temperature of ≥70°C.

- Filament pre-treatment: Dry at 120°C for 2~4 hours to prevent moisture-induced bubbles and filament breaks.

- Nozzle diameter: 0.4~1.0 mm (for fiber-reinforced formulations, ≥0.6 mm is recommended).

- Layer height: 0.1~0.25 mm; print speed typically 10~40 mm/s (depending on machine type and formulation).

- Post-processing: Annealing: 200°C/2h → slow cooling (to enhance crystallinity and strength); specific processes must be validated per part.

Maintenance

Under normal operating conditions, inspection items include:

- After use, store the filament in a vacuum bag with desiccant

- Storage environment humidity ≤15% RH

- If the filament surface has moisture or bubbles, re-dry it

Certification

| Certification | Standard | Region |

|---|---|---|

| RoHS | RoHS 2011/65/EU | Europe |

| REACH | EC 1907/2006 | Europe |

| FDA | 21 CFR 177.2415 | United States |

| ISO | ISO 9001:2015 | Global |